Building Hull By sv Prairie SeaShell on 22 Apr, 2005 3:19 PM Building the hull

How I built a 38 foot sailboat - Phase 2

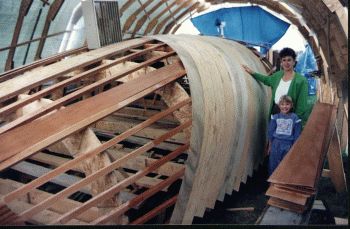

Covering the form

This is the first layer of the hull. It is 1/8th inch thick mahogany plywood, The horizontal pieces that you see are old growth fir. You won't see this kind of wood in your local lumber yard. The plywood was attached to the stingers with silicon bronze ring nails. You can see my two helpers in the picture.

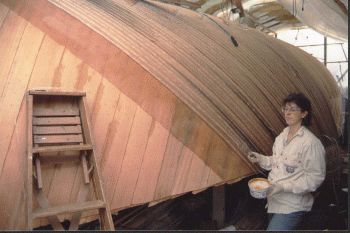

Cedar veneer

This is the second layer cedar veneer. The veneer came from a sawmill in Oregon that will pick a special tree to slice up into veneer. the pieces were about 17 feet long and 10 inches wide and 1/8 inch thick, they did not have any knots or blemishes.

Veneer

We were able to glue on venier when it got cold because I put propane heaters under the hull and because the hull was upside down the heat was trapped under the hull and kept it warm so that the epoxy would set up.

Applying epoxy

The epoxy was mixed with wood flour to thicken it then it was put on with a serated bade. The cedar venier was trimed to butt up to the previous piece of venier and stapled on place. The staples were through a plastic band to make them eaisier to remove the next day after the epoxy had set up. In the four layers that were stapled on 75,000 staples were put in and I hope all 75,000 were removed.

Fibreglass

After I had 5 layers of wood on. Two layers of fiberglass were put on. We started at the front at 5 AM and continued until 10 PM to get one side done as we could not stop half way or we would have a very bad seam.

Previous: Only in Your Dreams

Previous: Only in Your Dreams ...

Next: Finishing Hull and Interior Walls ...